With the arrival of late autumn, the brewing season is now in full swing.

Although an increasing number of breweries are now equipped with air-conditioning facilities and are engaged in three- or four-season brewing, the majority of breweries in the prefecture start brewing the current season's sake around October, with the majority of breweries still making sake in the cooler temperatures of late autumn, winter and early spring, when the air is cleaner due to snow.

In this article, I would like to reintroduce sake brewing and a year in the life of a sake brewery, following the brewing of the sake mother, which I was able to observe at the Sasashuku Sake Brewery in Nishigama-ku, Niigata City.

At the Sasashuku Sake Brewery in Nishigama-ku, Niigata City, along the old Hokkoku Highway, prayers for brewing safety were held on 4 October at a great peace day this season.

At the Sasashuku Sake Brewery in Nishigama-ku, Niigata City, along the old Hokkoku Highway, prayers for brewing safety were held on 4 October at a great peace day this season.

The Sasashuku Sake Brewery, founded in 1899 (Meiji 32), worships Matsuo-taijin, the god of sake, and has asked the local Shingon sect temple, Senjoin, to pray to him for generations.

Photo shows the 2017 brewing safety prayer.

'There may not be many warehouses that ask for help from a temple,' says president Ryosuke Sasaguchi. 'It's a Shingon sect, so they 'kuji' (cut the nine syllables) to remove misfortune.

It would certainly be unusual for the nine Chinese characters for Imin, Hyouhei, Toushi, Sha...... and the incantation to tie a sign in the hand and draw a grid of lines in the air to be used in a prayer for brewing safety.

On 18 October, the first washing of rice of the season took place.

On the day we visited for the interview, the brewing of the sake mother was to take place. The sake mother is used in the (main) brewing process and acts as a kind of starter with a large amount of healthy yeast cultivated. It is also called a yeast starter and is the very core of the sake.

Rice has little sugar to begin with, but the koji turns the rice starch into sugar, which is then turned into alcohol by the yeast.

The rice used by Sasashuku Brewery is Kame-no-o, Koshitanrei, Gohyakumangoku, Yukinosei, Koshibuki and Koshihikari; from 2019, all rice is grown locally in Niigata City.

Toji (master brewer) Yoichi Hatakeyama and brewer Yusuke Ohno are in charge of sake brewing at Sasashuku Brewery. President Sasaguchi also provides support when time permits. Takako Honda, who has worked at the Sasashuku Brewery for more than 30 years and knows the brewery better than anyone else, also joins in at key points. She is the strongest helper.

8 am. Weigh rice that has been washed and drained the day before to check water absorption.

The rice is carried, transferred from the colander to the steamer and flattened. Mr Sasaguchi jokingly says, "Ohno used to be a member of the baseball team, so he's good at playing with the steamer. The nervous expression on Mr Ono's face relaxes.

Today, the sake mother for the regular representative brand, Sasashuku Niigata Mark, is brewed, and the rice used for the brew is Koshibuki, which is steamed.

In sake brewing, rice is used for two purposes: one is as rice for the sake mother and main brewing process, and the other is to make koji (malted rice).

The most popular regular sake in the local area, Niigata-jirushi, has a rice polishing ratio of 65%. The rice polishing ratio for honjozo sake, which is part of the specified name sake category other than regular sake, is 70% or less, which means that the rice polishing ratio alone is as high as that for specified name sake.

Niigata sake breweries do not skimp on regular sake, also known as everyday sake. The rice is thoroughly polished to produce a clean, fresh taste, which is the goal of each brewery and product. It is the pride of a local sake brewery that has been passed down from generation to generation to take care of the sake that the local people look forward to every day.

Preparation of steamed rice. The steel steamer is fastened securely on all sides with metal fittings to prevent it from being lifted up by the force of the steam.

Ready with a shout of 'Alright'. When the steam has covered the entire rice, the cloth is covered.

From here, the rice is heated by steam for about one hour to steam the rice.

During this time, preparations are made for the preparation of the sake mother.

At the 'Kare Rashiba', where the finished koji is dried, the koji used to prepare the mother of sake, which took about two days to finish, was being prepared.

The koji is taken to the brewing room and put into a tank filled with water to make 'water koji'.

Mix well with an oar. The temperature is always checked after each operation. Temperature control is important for sake brewing.

Mix well with an oar. The temperature is always checked after each operation. Temperature control is important for sake brewing.

And after the work, cleaning. Cleaning and washing up to keep clean takes up a large part of the working time of the brewery.

And after the work, cleaning. Cleaning and washing up to keep clean takes up a large part of the working time of the brewery.

Mr Ohno assembles a filter machine to be used for filtration work, which is planned after the brewing of the mother of sake. This filtering machine is a small type. The net, filter and frame are stacked in sequence.

Mr Ohno assembles a filter machine to be used for filtration work, which is planned after the brewing of the mother of sake. This filtering machine is a small type. The net, filter and frame are stacked in sequence.

Filtration is one of the finishing touches after the sake has been pressed. Sake without filtration is 'unfiltered'.

Mr Ono is from Niigata City. He has been brewing sake for eight years. After graduating from university in the Kansai region, he worked in Osaka while working in another industry, where he fell in love with sake. He has worked at two breweries in the prefecture, and since last season he has been working at Sasashuku Sake Brewery under the guidance of Master Brewer Hatakeyama.

Mr Hatakeyama washes the colander that contained the rice. The work continues without rest.

Mr Honda prepares the cloth to carry the steamed rice.

Mr Honda prepares the cloth to carry the steamed rice.

Puffed up with steam.

About 20 minutes after making water malt, lactic acid and yeast are added.

Lactic acid on the left, yeast on the right.

Lactic acid on the left, yeast on the right.

'First we sterilise it with lactic acid, then we add the yeast,' says Hatakeyama.

The yeast used in Niigata-Jirushi is S-3. This yeast was developed by Dr Tadao Hiroi, a doctor of agriculture and former head of the Niigata Brewery Research Institute.

The yeast used in Niigata-Jirushi is S-3. This yeast was developed by Dr Tadao Hiroi, a doctor of agriculture and former head of the Niigata Brewery Research Institute.

After serving as director of the prefectural testing centre, Mr Hiroi was an advisor to the Echigo Chugakukai (1990-2004), which provides guidance on sake brewing to about 10 breweries in the prefecture. He also received guidance at Sasashuku Sake Brewery, from the basics to advanced techniques.

Oar the rice, stir it well, check the temperature and finish the process. It is time for the rice to be steamed.

About 1 hour after the rice is added, the cloth is removed and the steamed rice is dug out.

About 1 hour after the rice is added, the cloth is removed and the steamed rice is dug out.

Steamed rice is transferred to a cooler while the steaming condition is checked by hand. The steaming condition is checked by taking a handful of rice and making 'hinerimochi', which is crushed and kneaded by hand.

Steamed rice is transferred to a cooler while the steaming condition is checked by hand. The steaming condition is checked by taking a handful of rice and making 'hinerimochi', which is crushed and kneaded by hand.

This is 'twisted rice cake'.

Mr Hatakeyama checks the temperature of the rice in the cooler.

If the quantity is large, it is flown to the preparation room by air shooter, but today it is a small quantity, so it is wrapped in cloth and carried by hand.

Steamed rice is placed in the sake mother tank in the preparation room.

Mix well and evenly with paddles.

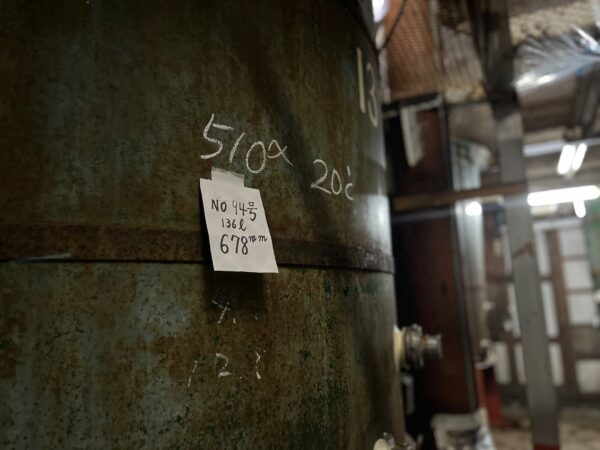

Once the quantity is measured and the temperature is checked, the brewing of the sake mother is finished.

The tank is a substitute for a note board.

The tank is a substitute for a note board.

Sake mothers that have finished brewing. On the 12th day after the stocking, the first soze (first stocking) of the main brewing process is scheduled to take place. The brewing process is divided into three parts: soze, naka and tomeshi.

The day after the addition, the brewer takes a 'dance' to rest. By taking a rest, an environment is created in which the yeast can easily cultivate.

After the brewing of the distillate, the moromi period lasts 20-30 days, depending on the type of sake, before the pressing process begins. During this period, the toji and brewers repeatedly check the temperature and analyse the ingredients, and make decisions on when to press the mash by observing the expression of the mash. The ability to make the right decision determines the taste of the sake.

Finishing the last brewing of the season is called 'koshikoshi' in sake breweries.

The Sasashuku Brewery's 'steamer down' is scheduled for around March next year.

As soon as the brewer finishes preparing the mother of sake, he returns to the steaming area to clean the steamer.

Cloths and tools are washed in hot water similar to the boiling water used for steaming rice. There is no waste in the brewing process.

When the tidying up is done, it's time for a 10:00 a.m. smoke.

The space where the brewers rest is called hiroshiki. At the Sasashuku brewery, it is called 'iba'. The terminology used only in the brewery is also an important part of the sake culture.

After the break, Hatakeyama-san starts the filtration process.

This is the finishing work on the 'Habataki 21st Century', which was prepared last season.

This is a honjozo class sake made from 'Gohyakumangoku' and 'Yukinosei' and sold exclusively at local sake outlets towards the end of each year.

This is a honjozo class sake made from 'Gohyakumangoku' and 'Yukinosei' and sold exclusively at local sake outlets towards the end of each year.

Mr Hatakeyama tasting sake after filtration. First, he checks the aroma and then the taste.

Mr Hatakeyama tasting sake after filtration. First, he checks the aroma and then the taste.

Mr Hatakeyama is a fourth-year student of Niigata Sake School. There are 20 of his classmates, and they used to have reunions once a year before the Corona disaster. Some of his classmates are current and former toji.

The president, Mr Sasaguchi, is also a graduate of the Sake School. The Niigata Sake School supports Niigata's brewing technology and network.

Mr Ohno, a brewer, says that the best part of brewing sake is when the customers say how delicious it tastes after the brewing process is finished. He likes his sake heated, especially if it's hotter than 'jumped-out hot'. It goes well with all kinds of food.

I'd like to make some good heated sake," he says, his eyes sparkling.

Since 2016, Sasashuku Brewery has been involved in the Challenge Brew initiative, in which a tank of sake is brewed together with people from various walks of life, including sake retailers, izakayas and sake lovers, from the planning stage.

Since 2016, Sasashuku Brewery has been involved in the Challenge Brew initiative, in which a tank of sake is brewed together with people from various walks of life, including sake retailers, izakayas and sake lovers, from the planning stage.

It was suspended last season but is back this season! He says he can't disclose details, but says: "It's a sweet sake, a dessert kind of sake. ......", says Sasaguchi.

This season is also going to be a 'fun' brew, incorporating a variety of ideas and a playful spirit. Let's hope for the best.

The Sasashuku Brewery also plans to start a new business next spring.

'We haven't decided on an official name yet, but we are thinking of a hands-on facility like the Sasashuku Brewery's Koji Kitchen,' says Sasaguchi. The current shop space will be extensively renovated to create a space that can be enjoyed by all generations.

Breweries of sake, wine and beer are dotted along the Hokkoku Kaido road from Nishi-ku to Nishikaga-ku, Niigata City. The Takano Sake Brewery in Nishi Ward is also preparing an open factory for next spring. We would like to take a tour of the sake breweries along the Kaido, paying attention to the efforts of each one.

高橋真理子

2022.10.31

advertisement